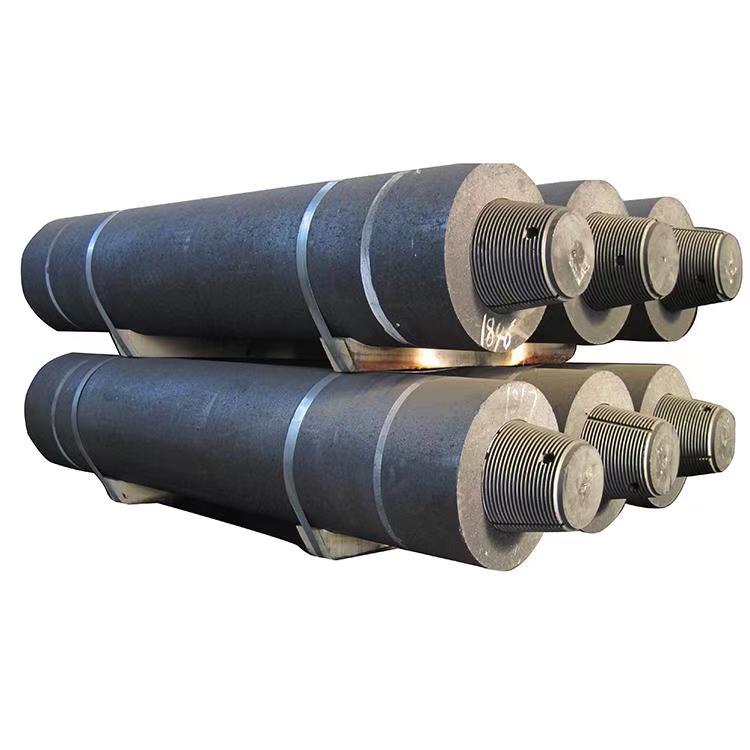

Mfundo yogwirira ntchito ya ma elekitirodi a graphite a Ultra-high (UHP) imachokera pazochitika za arc discharge. Pogwiritsa ntchito mphamvu zawo zapadera zamagetsi, kukana kutentha kwambiri, komanso makina, maelekitirodiwa amathandiza kuti mphamvu yamagetsi isinthe kukhala mphamvu yotentha mkati mwa malo omwe amasungunuka kwambiri, motero amayendetsa zitsulo. M'munsimu ndikuwunika mwatsatanetsatane njira zawo zogwirira ntchito:

1. Kutulutsa kwa Arc ndi Kusintha kwa Mphamvu ya Magetsi kupita ku Thermal

1.1 Arc Formation Mechanism

Pamene UHP graphite maelekitirodi ndi Integrated mu zipangizo smelting (mwachitsanzo, magetsi arc ng'anjo), amakhala ngati conductive TV. Kutulutsa kwamphamvu kwambiri kumapanga arc yamagetsi pakati pa nsonga ya elekitirodi ndi ng'anjo yamoto (mwachitsanzo, zitsulo zachitsulo, chitsulo). Arc iyi imakhala ndi njira ya plasma yopangidwa ndi ionization ya gasi, yomwe kutentha kwake kumapitilira 3000 ° C -kupitilira kutentha kwanthawi zonse.

1.2 Kutumiza Mphamvu Moyenera

Kutentha kwakukulu kopangidwa ndi arc kumasungunula ng'anjo yamoto. Ma elekitirodi 'apamwamba amagetsi amagetsi (okhala ndi resistivity otsika ngati 6-8 μΩ·m) amaonetsetsa kuti mphamvu zowonongeka ziwonongeke panthawi yotumizira, kukhathamiritsa kugwiritsa ntchito mphamvu. Popanga zitsulo za arc ng'anjo yamagetsi (EAF), mwachitsanzo, ma elekitirodi a UHP amatha kuchepetsa kusungunula ndi 30%, zomwe zimakulitsa zokolola.

2. Katundu Wazinthu ndi Kutsimikizika Kwantchito

2.1 Kukhazikika Kwamapangidwe Otentha Kwambiri

Ma elekitirodi amatha kupirira kutentha kwambiri kumachokera ku mawonekedwe ake a crystalline: maatomu a kaboni wosanjikiza amapanga maukonde ogwirizana kudzera mu sp² hybridization, yokhala ndi interlayer yomangirira kudzera mu mphamvu za van der Waals. Kapangidwe kameneka kamakhalabe ndi mphamvu zamakina pa 3000 ° C ndipo kumapereka kukana kwapadera kwa kutentha (kupitilira kusinthasintha kwa kutentha mpaka 500 ° C / min), ma elekitirodi azitsulo opambana.

2.2 Kukaniza Kukula kwa Matenthedwe ndi Kugwa

Maelekitirodi a UHP amawonetsa kutsika kwamphamvu kwa kutentha (1.2×10⁻⁶/°C), kuchepetsa kusintha kwa mawonekedwe pa kutentha kokwera ndikuletsa kupanga ming'alu chifukwa cha kupsinjika kwa kutentha. Kukana kwawo kukwawa (kutha kukana kupunduka kwa pulasitiki pansi pa kutentha kwakukulu) kumakongoletsedwa ndi singano ya coke yaiwisi yaiwisi ndi njira zotsogola za graphitization, kuwonetsetsa kukhazikika kwapang'onopang'ono pakatha ntchito yayitali yayitali.

2.3 Kulimbana ndi Oxidation ndi Corrosion Resistance

Mwa kuphatikiza ma antioxidants (mwachitsanzo, borides, silicides) ndikuyika zokutira pamwamba, kutentha kwa ma electrode oxidation kumakwera pamwamba pa 800 ° C. Kusakhazikika kwa mankhwala motsutsana ndi slag yosungunuka panthawi yosungunula kumachepetsa kugwiritsa ntchito maelekitirodi kwambiri, kukulitsa moyo wautumiki ku 2-3 kuposa ma elekitirodi wamba.

3. Kugwirizana kwa Njira ndi Kukonzekera Kwadongosolo

3.1 Kachulukidwe Panopa ndi Mphamvu Zamphamvu

Ma elekitirodi a UHP amathandizira kachulukidwe kakali pano kupitilira 50 A/cm². Akaphatikizidwa ndi ma transfoma apamwamba kwambiri (mwachitsanzo, 100 MVA), amalowetsa mphamvu ya ng'anjo imodzi yopitilira 100 MW. Kapangidwe kameneka kamapangitsa kuti matenthedwe alowemo akamasungunuka - mwachitsanzo, kuchepetsa kugwiritsa ntchito mphamvu pa tani imodzi ya silicon pakupanga ferrosilicon kukhala pansi pa 8000 kWh.

3.2 Kuyankha Kwamphamvu ndi Kuwongolera Njira

Makina amakono osungunula amagwiritsa ntchito Smart Electrode Regulators (SERs) kuti aziyang'anira mosalekeza momwe ma electrode alili, kusinthasintha kwapano, ndi kutalika kwa ma arc, kusunga kuchuluka kwa ma electrode mkati mwa chitsulo cha 1.5-2.0 kg/t. Kuphatikizidwa ndi kuyang'anira mlengalenga wa ng'anjo (mwachitsanzo, CO/CO₂ ratios), izi zimapangitsa kuti ma electrode-charge agwirizane bwino.

3.3 Dongosolo la Synergy ndi Kupititsa patsogolo Mphamvu Zamagetsi

Kutumiza maelekitirodi a UHP kumafuna zida zothandizira, kuphatikiza makina opangira magetsi othamanga kwambiri (mwachitsanzo, ma 110 kV mwachindunji), zingwe zoziziritsa madzi, ndi mayunitsi otolera fumbi ogwira ntchito. Ukadaulo wobwezeretsa kutentha kwa zinyalala (mwachitsanzo, kuphatikizika kwa gasi wamagetsi arc) amakweza mphamvu zonse kupitilira 60%, zomwe zimathandizira kugwiritsa ntchito mphamvu pang'onopang'ono.

Zomasulirazi zimakhala zolondola mwaukadaulo pomwe zikutsatira mfundo za mawu amaphunziro/zamakampani, kuwonetsetsa kuti anthu apadera azimveka bwino.

Nthawi yotumiza: May-06-2025