Makhalidwe a 1.EDM a zipangizo za graphite.

1.1.Kutulutsa liwiro la makina.

Graphite ndi zinthu zopanda zitsulo zomwe zimasungunuka kwambiri 3, 650 ° C, pamene mkuwa uli ndi malo osungunuka a 1, 083 ° C, kotero electrode ya graphite imatha kupirira mikhalidwe yayikulu yamakono.

Pamene kumaliseche m'dera ndi kukula kwa elekitirodi kukula, ubwino mkulu dzuwa akhakula Machining zinthu graphite ndi zoonekeratu.

Kutentha kwa graphite ndi 1/3 ya mkuwa, ndipo kutentha komwe kumapangidwa panthawi ya kutulutsa kungagwiritsidwe ntchito kuchotsa zipangizo zachitsulo bwino. Choncho, processing dzuwa la graphite ndi apamwamba kuposa elekitirodi mkuwa sing'anga ndi processing bwino.

Malinga ndi zomwe zidachitika pakukonza, kuthamanga kwa ma electrode a graphite ndi 1.5 ~ 2 nthawi mwachangu kuposa ma elekitirodi amkuwa pansi pamikhalidwe yoyenera.

1.2.Kugwiritsa ntchito ma elekitirodi.

Graphite elekitirodi ali ndi khalidwe kuti akhoza kupirira zinthu mkulu panopa, kuwonjezera, pansi pa chikhalidwe yoyenera roughing kolowera, kuphatikizapo mpweya zitsulo workpieces opangidwa pa Machining kuchotsa okhutira ndi ntchito madzimadzi pa kutentha kuwonongeka kwa mpweya particles, ndi polarity zotsatira, pansi pa zochita za kuchotsedwa tsankho mu okhutira, mpweya particles adzatsatira elekitirodi pamwamba kupanga zoteteza mu graphite wosanjikiza, kuonetsetsa imfa yaing'ono graphite kapena machi. kutaya”.

Kutayika kwakukulu kwa electrode mu EDM kumachokera ku makina ovuta. Ngakhale kuti chiwongoladzanja ndichokwera kwambiri pokonzekera kumaliza, kutayika konseko kumakhala kochepa chifukwa cha malipiro ang'onoang'ono a makina omwe amasungidwa magawo.

Nthawi zambiri, kutayika kwa elekitirodi ya graphite ndikocheperako poyerekeza ndi ma elekitirodi amkuwa pamakina ovuta kwambiri apano komanso pang'ono kuposa ma elekitirodi amkuwa pakumaliza kukonza. Kutayika kwa electrode kwa graphite electrode ndikofanana.

1.3.Makhalidwe apamwamba.

The tinthu awiri a graphite zakuthupi zimakhudza mwachindunji roughness pamwamba EDM. Zing'onozing'ono ndi momwe zimakhalira, kutsika kwapamwamba kungathe kupezeka.

Zaka zingapo zapitazo ntchito tinthu phi 5 microns m'mimba mwake graphite zakuthupi, pamwamba bwino angathe kukwaniritsa VDI18 edm (Ra0.8 microns), masiku ano m'mimba mwake njere wa zipangizo graphite akwanitsa kukwaniritsa mkati 3 microns wa phi, pamwamba yabwino akhoza kukwaniritsa khola VDI12 edm (Ra0.4 mu m) kapena kuposa apamwamba graphite mlingo, koma ma electrographed apamwamba kwambiri.

Zida zamkuwa zimakhala ndi mphamvu zochepa komanso zosakanikirana, ndipo zimatha kukonzedwa mokhazikika pansi pazovuta. Kuuma kwapamwamba kumatha kukhala kosakwana Ra0.1 m, ndipo kumatha kukonzedwa ndi galasi.

Chifukwa chake, ngati makina otulutsa amatsata bwino kwambiri pamwamba, ndi bwino kugwiritsa ntchito zinthu zamkuwa ngati ma elekitirodi, womwe ndi mwayi waukulu wa elekitirodi yamkuwa pamagetsi a graphite.

Koma elekitirodi yamkuwa pansi pa chikhalidwe chachikulu panopa, elekitirodi pamwamba n'zosavuta kukhala akhakula, kuoneka ngakhale mng'alu, ndi graphite zipangizo sakanakhala ndi vutoli, pamwamba roughness chofunika VDI26 (Ra2.0 microns) za processing nkhungu, ntchito elekitirodi graphite zikhoza kuchitika kuchokera coarse kuti processing wabwino, amazindikira yunifolomu pamwamba zotsatira, pamwamba zolakwika.

Kuonjezera apo, chifukwa cha mapangidwe osiyanasiyana a graphite ndi mkuwa, malo otsekemera amadzimadzi a graphite electrode amakhala okhazikika kuposa a electrode yamkuwa. Choncho, pamene pamwamba roughness wa VDI20 kapena pamwamba kukonzedwa, pamwamba granularity wa workpiece kukonzedwa ndi elekitirodi graphite ndi wosiyana kwambiri, ndipo zotsatira pamwamba pa njere ndi bwino kuposa kutulutsa pamwamba zotsatira za elekitirodi mkuwa.

1.4.Kulondola kwa makina.

The coefficient of matenthedwe kukula kwa graphite zakuthupi ndi yaing'ono, ndi coefficient of matenthedwe kukula kwa zinthu zamkuwa ndi 4 nthawi graphite zakuthupi, kotero mu kumaliseche processing, graphite elekitirodi ndi zochepa sachedwa mapindikidwe kuposa elekitirodi mkuwa, amene angapeze kwambiri khola ndi odalirika processing olondola.

Makamaka pamene nthiti yakuya ndi yopapatiza ikukonzedwa, kutentha kwapafupi kumapangitsa kuti electrode yamkuwa ikhale yosavuta, koma ma electrode a graphite satero.

Kwa electrode yamkuwa yokhala ndi chiŵerengero chakuya-m'mimba mwake, mtengo wina wowonjezera kutentha uyenera kulipidwa kuti uwongolere kukula kwake panthawi yokonza makina, pamene electrode ya graphite sikufunika.

1.5.Kulemera kwa elekitirodi.

Zinthu za graphite ndizochepa kwambiri kuposa zamkuwa, ndipo kulemera kwa electrode ya graphite ya voliyumu yomweyi ndi 1/5 yokha ya electrode yamkuwa.

Zitha kuwoneka kuti kugwiritsa ntchito graphite ndikoyenera kwambiri kwa electrode ndi voliyumu yayikulu, yomwe imachepetsa kwambiri katundu wa spindle wa chida cha makina a EDM. The elekitirodi sadzachita kusokoneza clamping chifukwa kulemera kwake lalikulu, ndipo adzatulutsa kusamuka kusamutsidwa mu processing, etc. Tingaone kuti n'zofunika kwambiri ntchito graphite elekitirodi mu yaikulu nkhungu processing.

1.6.Kuvuta kwa Electrode.

Kuchita kwa makina a graphite ndikwabwino. Kukana kudula ndi 1/4 yokha ya mkuwa. Pansi pamikhalidwe yoyenera, mphamvu ya mphero ya graphite elekitirodi ndi nthawi 2 ~ 3 kuposa electrode yamkuwa.

Elekitirodi ya graphite ndiyosavuta kuyimitsa Angle, ndipo itha kugwiritsidwa ntchito pokonza chogwirira ntchito chomwe chiyenera kumalizidwa ndi maelekitirodi angapo kukhala electrode imodzi.

Wapadera tinthu dongosolo la zinthu graphite amalepheretsa burrs kuchitika pambuyo elekitirodi mphero ndi kupanga, amene akhoza mwachindunji kukwaniritsa zofunikira ntchito pamene burrs sali kuchotsedwa mosavuta mu chitsanzo zovuta, motero kuthetsa ndondomeko kupukuta pamanja la elekitirodi ndi kupewa kusintha mawonekedwe ndi kukula zolakwika chifukwa cha kupukuta.

Tikumbukenso kuti, chifukwa graphite ndi kudzikundikira fumbi, mphero graphite kutulutsa zambiri fumbi, kotero makina mphero ayenera kukhala ndi chisindikizo ndi fumbi kusonkhanitsa chipangizo.

Ngati kuli kofunikira kugwiritsa ntchito edM pokonza ma elekitirodi a graphite, ntchito yake yokonza si yabwino ngati zinthu zamkuwa, kuthamanga kwachangu kumakhala pafupifupi 40% pang'onopang'ono kuposa mkuwa.

1.7.Kuyika ndi kugwiritsa ntchito Electrode.

Zinthu za graphite zili ndi katundu wabwino wolumikizana. Itha kugwiritsidwa ntchito kumangiriza ma graphite ndi makinawo pogaya ma elekitirodi ndi kutulutsa, zomwe zimatha kupulumutsa njira yopangira phula pazitsulo za elekitirodi ndikusunga nthawi yogwira ntchito.

Zinthu za graphite zimakhala zowonongeka, makamaka electrode yaying'ono, yopapatiza komanso yayitali, yomwe imakhala yosavuta kusweka pamene ikugwiritsidwa ntchito ndi mphamvu yakunja, koma imatha kudziwa nthawi yomweyo kuti electrode yawonongeka.

Ngati ndi electrode yamkuwa, imangopindika osati kusweka, zomwe zimakhala zoopsa komanso zovuta kuzipeza pogwiritsira ntchito, ndipo zimatsogolera mosavuta ku zidutswa za workpiece.

1.8.Mtengo.

Zinthu zamkuwa ndizinthu zosasinthika, mtengo wamtengo wapatali udzakhala wokwera mtengo, pamene mtengo wa graphite umakhala wokhazikika.

Mkuwa zakuthupi mtengo kukwera m'zaka zaposachedwapa, opanga zazikulu za graphite kuwongolera ndondomeko kupanga graphite kupanga mwayi mpikisano, tsopano, pansi buku lomwelo, ambiri a graphite elekitirodi mtengo zinthu ndi mtengo wa mkuwa elekitirodi zipangizo ndithu, koma graphite akhoza kukwaniritsa processing kothandiza, kuposa kugwiritsa ntchito elekitirodi mkuwa kupulumutsa chiwerengero chachikulu cha maola ogwira ntchito, yofanana mwachindunji ndi kupanga mtengo wofanana.

Mwachidule, pakati pa 8 edM makhalidwe a graphite elekitirodi, ubwino wake n'zoonekeratu: dzuwa la mphero elekitirodi ndi kumaliseche processing ndi bwino kwambiri kuposa electrode mkuwa; Elekitirodi yayikulu imakhala yolemera pang'ono, kukhazikika bwino kwa mawonekedwe, ma elekitirodi owonda siwosavuta kupunduka, komanso mawonekedwe apamwamba kuposa ma elekitirodi amkuwa.

Kuipa kwa zinthu za graphite ndikuti sikoyenera kukonza bwino kutulutsa pansi pa VDI12 (Ra0.4 m), komanso kugwiritsa ntchito bwino kwa edM kupanga elekitirodi ndi otsika.

Komabe, kuchokera ku mfundo zothandiza, chimodzi mwa zifukwa zofunika zimakhudza Kukwezeleza ogwira graphite zipangizo ku China ndi kuti makina apadera graphite processing chofunika kwa maelekitirodi mphero, amene amaika patsogolo zofunika zatsopano processing zida mabizinesi nkhungu, mabizinesi ena ang'onoang'ono mwina alibe chikhalidwe ichi.

Kawirikawiri, ubwino wa ma electrode a graphite umakhudza nthawi zambiri za edM processing, ndipo ndizoyenera kutchuka ndi kuzigwiritsa ntchito, zomwe zimakhala ndi phindu lokhalitsa. Kuperewera kwa kukonza bwino pamwamba kungapangidwe pogwiritsa ntchito ma electrode amkuwa.

2.Kusankhidwa kwa graphite electrode zipangizo za EDM

Pazinthu za graphite, pali zizindikiro zinayi zotsatirazi zomwe zimatsimikizira momwe zinthuzo zikuyendera:

1) Avereji tinthu awiri a zinthu

The pafupifupi tinthu awiri a zinthu mwachindunji zimakhudza kumaliseche chikhalidwe cha zinthu.

Zing'onozing'ono za tinthu tating'onoting'ono ta graphite ndizomwe zimakhala zofanana kwambiri, zomwe zimatuluka zimakhala zokhazikika, zimakhala bwino kwambiri, ndipo kutayika kumakhala kochepa.

Kukula kwakukulu kwa tinthu tating'onoting'ono ndi, kuchuluka kwa kuchotsedwa bwino kumatha kupezeka pamakina olakwika, koma mawonekedwe ake otsiriza ndi osauka ndipo kutaya ma elekiti ndi yayikulu.

2) Mphamvu yopindika ya zinthu

Mphamvu yosinthasintha ya chinthu ndikuwonetseratu mphamvu zake, kusonyeza kulimba kwa mkati mwake.

Zinthu zokhala ndi mphamvu zambiri zimakhala ndi ntchito yabwino yokana kutulutsa. Kwa electrode yolondola kwambiri, zinthu zomwe zili ndi mphamvu zabwino ziyenera kusankhidwa momwe zingathere.

3) Kuuma kwa m'mphepete mwa zinthu

Graphite ndi yolimba kuposa zida zachitsulo, ndipo kutayika kwa chida chodulira ndi chachikulu kuposa chitsulo chodula.

Pa nthawi yomweyo, kuuma mkulu wa graphite zakuthupi mu kumaliseche kutayika ulamuliro bwino.

4) The rensinsitive chibadidwe cha zinthu

Kutulutsa kwa zinthu za graphite zokhala ndi zopinga zapamwamba kudzakhala pang'onopang'ono kusiyana ndi kutsika kwa resistivity.

Kukwera kwa resistivity yachibadwa, kumachepetsa kutayika kwa electrode, koma kumtunda kwa resistivity yachibadwa, kukhazikika kwa kutulutsa kumakhudzidwa.

Pakali pano, pali mitundu yosiyanasiyana ya ma graphite yomwe ikupezeka kuchokera kwa otsogola padziko lonse lapansi opanga ma graphite.

Nthawi zambiri malinga ndi pafupifupi tinthu awiri a zipangizo graphite kuti wachinsinsi, tinthu m'mimba mwake ≤ 4 mamita limatanthauzidwa ngati graphite zabwino, particles mu 5 ~ 10 mamita limatanthauzidwa ngati sing'anga graphite, particles mu 10 mamita pamwamba limatchedwa coarse graphite.

Zing'onozing'ono za tinthu tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono, zinthu za graphite zitha kusankhidwa molingana ndi zofunikira komanso mtengo wa EDM.

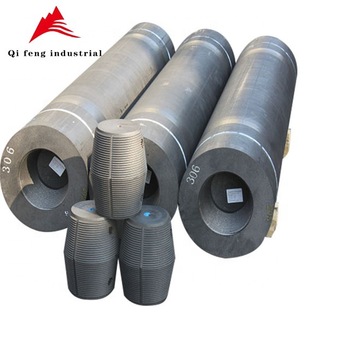

3.Kupanga electrode ya graphite

Ma electrode a graphite amapangidwa makamaka ndi mphero.

Kuchokera pamalingaliro aukadaulo waukadaulo, ma graphite ndi mkuwa ndi zida ziwiri zosiyana, ndipo mawonekedwe awo odulidwa ayenera kudziwa bwino.

Ngati graphite elekitirodi kukonzedwa ndi ndondomeko mkuwa elekitirodi, mavuto mosalephera kuchitika, monga pafupipafupi fracture ya pepala, amene amafuna kugwiritsa ntchito zida zoyenera kudula ndi magawo kudula.

Machining graphite elekitirodi kuposa mkuwa elekitirodi chida kuvala, pa nkhani zachuma, kusankha carbide chida ndicho chuma kwambiri, kusankha diamondi ❖ kuyanika chida (chotchedwa graphite mpeni) mtengo ndi okwera mtengo, koma diamondi ❖ kuyanika chida moyo wautali utumiki, mkulu processing mwatsatanetsatane, phindu lonse zachuma ndi zabwino.

Kukula kwa mbali ya kutsogolo kwa chida kumakhudzanso moyo wake wautumiki, 0 ° kutsogolo kwa chipangizocho kudzakhala mpaka 50% kuposa 15 ° kutsogolo kwa moyo wautumiki wa chida, kudula kukhazikika kulinso bwino, koma kuwonjezereka kwa Angle, kumapangitsa kuti makina apangidwe bwino, kugwiritsa ntchito 15 ° Angle ya chida kungathe kukwaniritsa bwino kwambiri.

Liwiro kudula mu Machining akhoza kusinthidwa malinga ndi mawonekedwe a elekitirodi, kawirikawiri 10m/mphindi, ofanana Machining a aluminiyamu kapena pulasitiki, chida kudula akhoza mwachindunji pa ndi kuchoka workpiece mu Machining akhakula, ndi chodabwitsa cha Angle kugwa ndi kugawikana n'zosavuta zimachitika pomaliza Machining, ndi njira ya kusala kudya kutengera njira yoyendera mpeni.

Graphite elekitirodi mu kudula ndondomeko adzabala fumbi kwambiri, pofuna kupewa graphite particles kukopa makina opota ndi wononga, pali njira ziwiri zazikulu pakali pano, mmodzi ndi ntchito yapadera graphite processing makina, winayo ndi wamba processing pakati refit, okonzeka ndi wapadera fumbi kusonkhanitsa chipangizo.

Makina apadera a graphite high speed mphero pamsika ali ndi mphamvu zambiri za mphero ndipo amatha kumaliza mosavuta kupanga maelekitirodi ovuta ndi olondola kwambiri komanso abwino pamwamba.

Ngati EDM ikufunika kupanga electrode ya graphite, tikulimbikitsidwa kugwiritsa ntchito zinthu zabwino za graphite ndi tinthu tating'onoting'ono.

Makina opangira ma graphite ndi osauka, momwe tinthu tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono titha kupewedwa.

4.EDM magawo a graphite electrode

Kusankhidwa kwa magawo a EDM a graphite ndi mkuwa ndizosiyana kwambiri.

Magawo a EDM makamaka akuphatikizapo panopa, pulse width, pulse gap ndi polarity.

Zotsatirazi zikufotokoza maziko ogwiritsira ntchito magawo akuluakuluwa.

Kachulukidwe kamakono ka ma elekitirodi a graphite nthawi zambiri amakhala 10 ~ 12 A/cm2, okulirapo kuposa a elekitirodi yamkuwa. Choncho, m'kati mwazomwe zimaloledwa m'dera lofananirako, kukula kwamakono kumasankhidwa, mofulumira kuthamanga kwa graphite kutayika kwachangu kudzakhala, kuchepa kwa electrode kudzakhala kochepa, koma kuuma kwapamwamba kudzakhala kokulirapo.

Kukula kwake kwa pulse ndiko, kuchepa kwa electrode kudzakhala kochepa.

Komabe, kugunda kwamphamvu kokulirapo kumapangitsa kuti kusasunthika kukhale koipitsitsa, ndipo liwiro la kukonza lichepe pang'onopang'ono komanso pamwamba pake.

Pofuna kuwonetsetsa kuti ma elekitirodi atayika pang'onopang'ono panthawi yokonza movutikira, m'lifupi mwake nthawi zambiri amagwiritsidwa ntchito, zomwe zimatha kuzindikira kutayika kochepa kwa ma elekitirodi a graphite pamene mtengo uli pakati pa 100 ndi 300 US.

Kuti mupeze zotsatira zabwino komanso zosasunthika za kutulutsa, m'lifupi mwake kuyenera kusankhidwa.

Nthawi zambiri, kugunda m'lifupi mwa elekitirodi graphite ndi pafupifupi 40% zochepa kuposa mkuwa elekitirodi.

The zimachitika kusiyana makamaka zimakhudza kumaliseche Machining liwiro ndi Machining bata. Mtengo wokulirapo, m'pamenenso kukhazikika kwa makina kudzakhala bwino, zomwe zimathandiza kuti pakhale kufanana kwapamwamba, koma liwiro la makina lidzachepetsedwa.

Pansi pa chikhalidwe chowonetsetsa kuti kukhazikika kwazitsulo, kugwiritsira ntchito kwapamwamba kungathe kupezedwa posankha kusiyana kochepa, koma pamene dziko lotulutsa liri losasunthika, kugwiritsira ntchito kwapamwamba kungathe kupezedwa posankha kusiyana kwakukulu kwa pulse.

Mu graphite elekitirodi kumaliseche Machining, zimachitika kusiyana ndi zimachitika m'lifupi zimayikidwa pa 1: 1, pamene mkuwa ma elekitirodi Machining, kugunda kusiyana ndi zimachitika m'lifupi zimayikidwa pa 1:3.

Pansi pa khola la graphite processing, chiŵerengero chofananira pakati pa kugunda kwapakati ndi kugunda kwapakati kungasinthidwe kukhala 2: 3.

Pankhani ya kugunda kwazing'ono, ndizopindulitsa kupanga chophimba chophimba pamwamba pa electrode, zomwe zimathandiza kuchepetsa kutaya kwa electrode.

Kusankhidwa kwa polarity kwa graphite electrode mu EDM kumakhala kofanana ndi electrode yamkuwa.

Malinga ndi mphamvu ya polarity ya EDM, makina abwino a polarity amagwiritsidwa ntchito popanga zitsulo zakufa, ndiko kuti, electrode imagwirizanitsidwa ndi mtengo wabwino wamagetsi, ndipo chogwiritsira ntchito chimagwirizanitsidwa ndi mzati woipa wa magetsi.

Pogwiritsa ntchito kukula kwakukulu kwamakono ndi kugunda, kusankha makina abwino a polarity amatha kutayika kwambiri kwa electrode. Ngati polarity ili yolakwika, kutayika kwa electrode kumakhala kwakukulu kwambiri.

Pokhapokha pamene pamwamba pafunika kukonzedwa bwino zosakwana VDI18 (Ra0.8 m) ndi kugunda m'lifupi ndi laling'ono kwambiri, ndi zoipa polarity processing ntchito kupeza bwino pamwamba khalidwe, koma electrode imfa ndi lalikulu.

Tsopano zida zamakina a CNC edM zili ndi magawo opangira ma graphite discharge.

Kugwiritsa ntchito magawo amagetsi ndikwanzeru ndipo kumatha kupangidwa kokha ndi katswiri wamakina opangira makina.

Nthawi zambiri, makina akhoza sintha wokometsedwa processing magawo posankha zinthu ziwiri, mtundu ntchito, pamwamba roughness mtengo ndi inputting malo processing, processing kuya, electrode kukula makulitsidwe, etc. Pa mapulogalamu.

Khazikitsani ma graphite elekitirodi ya edm makina chida laibulale magawo olemera processing, mtundu zakuthupi angasankhe mu coarse graphite, graphite, graphite limafanana zosiyanasiyana workpiece zakuthupi, kugawa mtundu ntchito kwa muyezo, poyambira, lakuthwa mfundo, dera lalikulu, patsekeke lalikulu, monga chabwino, komanso amapereka kutayika otsika, muyezo, Mwachangu mkulu wa processing mitundu yambiri ya kusankha ndi zina zotero.

5.Mapeto

Zatsopano za graphite elekitirodi ndizofunikira kutchuka mwamphamvu ndipo zabwino zake zidzazindikirika pang'onopang'ono ndikuvomerezedwa ndi makampani opanga nkhungu zoweta.

Kusankhidwa koyenera kwa zida za graphite electrode ndikuwongolera maulalo okhudzana ndiukadaulo kudzabweretsa magwiridwe antchito apamwamba, apamwamba kwambiri komanso phindu lotsika mtengo kwa mabizinesi opanga nkhungu.

Nthawi yotumiza: Dec-04-2020